Igiciro cya Plate y'icyuma ya Dx51d ifite ibyuma bya Galvanized nziza cyane

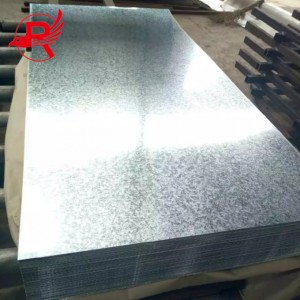

Hari amakuru amwe n'amwe agomba kwitabwaho mu gihe ukoresha hot-rolledUrupapuro rwa galvanize. Mbere na mbere, mu gihe cyo gutwara no kubika, hagomba kwirindwa kugongana no gushwanyagurika kugira ngo hirindwe kwangirika k'urukuta rwa galvani. Icya kabiri, mu gihe cyo gushyiraho no gutunganya, hagomba gutoranywa ibikoresho n'uburyo bikwiye kugira ngo hirindwe gushwanyaguza no kwangiza urwego rwa galvani. Byongeye kandi, mu gihe cyo gukoresha, impapuro za galvani zishyushye zigomba gusukurwa no kubungabungwa buri gihe, kandi umwanda n'imyanda iri hejuru bigomba gukurwaho ku gihe kugira ngo bikomeze kugaragara neza kandi bikore neza. Byongeye kandi, hagomba kwitabwaho kugira ngo hirindwe ko habaho imiti nka aside na alkali kugira ngo hirindwe ko impapuro za galvani zidashobora kwangirika. Amaherezo, hagomba kwitabwaho kugira ngo hirindwe ko zikoreshwa ahantu hashyushye cyane kugira ngo hirindwe ko urukuta rwa galvani rugira ingaruka ku mikorere y'urukuta rwa galvani. Muri rusange, gukoresha neza no kubungabunga ni ingenzi mu gutuma impapuro za galvani zishyushye zikora neza igihe kirekire. Gukoresha neza no kubungabunga bishobora kongera igihe cyo gukoresha impapuro za galvani no kwemeza ko zikoreshwa mu nzego zitandukanye.

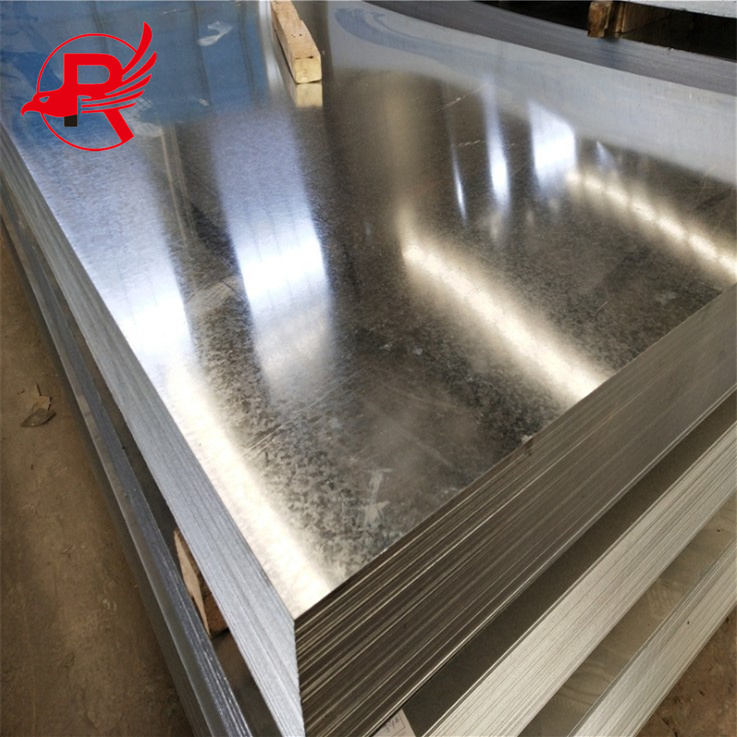

Ibati rya galvani ishyushye ifite ibyiza byinshi bituma ikoreshwa cyane mu nzego zitandukanye. Icya mbere, ubushobozi bwayo bwo kurwanya ingese ni kimwe mu byiza byayo by'ingenzi. Ibati rya galvani rishobora gukumira neza ubuso bw'icyuma kwangirika bitewe n'ikirere, amazi n'ibintu bya chimique, bityo ibyuma bigakomeza igihe cyo gukora. Icya kabiri, impapuro za galvani ishyushye zifite ubushobozi bwo kwangirika neza kandi zikwiriye ahantu hagomba kwihanganira kwangirika no kwangirika, nko mu nyubako, ibikoresho bya mekanike n'ahandi. Byongeye kandi, impapuro za galvani ishyushye nazo zifite ubushobozi bwo gutunganya neza kandi zishobora gutunganywa hakoreshejwe gukanda, gukanda, gusudira, nibindi, kandi zikwiriye gukora imiterere itandukanye igoye. Byongeye kandi, ubuso bw'ibati rya galvani ishyushye buraryoshye kandi ni bwiza, kandi bushobora gukoreshwa mu buryo butaziguye nk'ibikoresho byo gushushanya. Byongeye kandi, impapuro za galvani ishyushye nazo zifite ubushobozi bwiza bwo gutwara amashanyarazi kandi zikwiriye ingufu z'amashanyarazi, itumanaho n'ahandi. Muri rusange, ibati rya galvani ishyushye ryabaye kimwe mu bikoresho by'ingenzi mu bwubatsi, imashini, amashanyarazi, itumanaho n'ahandi bitewe no kudahangana kwabyo, kudashira no gutunganya neza.

Isahani y'icyuma gishyushye gikozwe muri galvanisedzikoreshwa cyane mu nzego zitandukanye. Mbere na mbere, mu rwego rw'ubwubatsi, amabati ashyushye akunze gukoreshwa mu buryo bwo gushyigikira no gusohora amazi mu nyubako. Ashobora gukoreshwa mu nyubako, mu nkuta z'ingazi, mu nkuta n'ibindi bice, kandi ashobora no gukoreshwa nk'igikoresho cy'ingenzi cy'imiyoboro y'amazi kuko ubushobozi bwayo bwo kurwanya ingese bushobora kongera igihe cyo kuyikoresha. Icya kabiri, mu rwego rw'inganda, amabati ashyushye akunze gukoreshwa mu gukora ibikoresho n'ibice bitandukanye, nk'ibigega byo kubikamo, imiyoboro, abafana, ibikoresho byo gutwara, nibindi. Ubudahangarwa bw'amabati butuma akoreshwa igihe kirekire mu nganda zikomeye, bigatuma ibikoresho bikoreshwa neza. Byongeye kandi, mu rwego rw'ubuhinzi, amabati ashyushye akoreshwa mu nganda afite akamaro kanini. Ashobora gukoreshwa mu buryo bwo kuhira ubuhinzi, mu nyubako zishyigikira imashini z'ubuhinzi, nibindi kuko ubushobozi bwayo bwo kurwanya ingese bushobora kurwanya kwangirika kw'ibikoresho bitewe n'imiti mu butaka. Byongeye kandi, mu rwego rwo gutwara, amabati ashyushye akunze gukoreshwa mu gukora ibice by'imodoka, ibice by'ubwato, nibindi, kuko ubushobozi bwayo bwo kurwanya ingese bushobora kongera igihe cy'akazi k'imodoka zitwara abantu. Muri rusange, amabati ashyushye afite akamaro kanini mu bwubatsi, inganda, ubuhinzi, ubwikorezi n'ibindi bikorwa, kandi kurwanya ingese bituma aba kimwe mu bikoresho byiza byo gukoresha mu bikoresho bitandukanye no mu nyubako.

| Ibipimo ngenderwaho bya tekiniki | EN10147, EN10142, DIN 17162, JIS G3302, ASTM A653 |

| Ingano y'icyuma | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490,SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); cyangwa iyabakiriya Ibisabwa |

| Ubunini | ibisabwa n'umukiriya |

| Ubugari | hakurikijwe ibyo umukiriya asabwa |

| Ubwoko bw'ipfundikizo | Icyuma gishyushye cya Galvani (HDGI) |

| Igipfukisho cya Zinc | 30-275g/m2 |

| Ubuvuzi bw'ubuso | Passivation (C), Oil (O), Lacquer sealing (L), Phosphating (P), Idavuwe (U) |

| Imiterere y'ubuso | Uburyo busanzwe bwo gusiga spangle (NS), uburyo bwo gusiga spangle buciriritse (MS), uburyo bwo gusiga spangle budafite spangle (FS) |

| Ireme | Byemejwe na SGS, ISO |

| ID | 508mm/610mm |

| Uburemere bwa Coil | Toni 3-20 kuri buri coil |

| Pake | Impapuro zirinda amazi ni ipaki y'imbere, icyuma cya galvani cyangwa urupapuro rw'icyuma gitwikiriwe ni ipaki y'inyuma, isahani yo kurinda ku ruhande, hanyuma igapfundikirwa na umukandara w'icyuma wirindwi. cyangwa hakurikijwe ibyo umukiriya akeneye |

| Isoko ryo kohereza ibicuruzwa mu mahanga | Uburayi, Afurika, Aziya yo Hagati, Aziya y'Amajyepfo y'Uburasirazuba, Uburasirazuba bwo Hagati, Amerika y'Epfo, Amerika y'Amajyaruguru, n'ibindi |

Q: Ese ni abakora uruganda rwa UA?

A: Yego, turi uruganda. Dufite uruganda rwacu ruherereye mu Mujyi wa Tianjin, mu Bushinwa.

Q: Ese nshobora kubona itegeko ryo kugerageza toni nyinshi gusa?

A: Birumvikana. Dushobora kohereza imizigo kuri wewe dukoresheje serivisi ya LCL. (Umutwaro muto w'amakontenari)

Q: Niba nta ngero zitanzwe?

A: Nta ngero zitangwa, ariko umuguzi ni we wishyura ibicuruzwa.

Q: Uri umucuruzi wa zahabu kandi ufite garanti y'ubucuruzi?

A: Dutanga zahabu mu myaka irindwi kandi twemera ubwishingizi bw'ubucuruzi.